Great news about the environment - share your stories

According to “breakthrough” new research, funded by a clutch of consumer goods firms, French scientists have discovered a plastic-eating enzyme they claim could offer an innovative recycling solution for millions of tonnes of toxic plastic waste material.

http://econews.com.au/64104/mutant-enzyme-created-by-scientists-recycles-plastic-bottles-in-hours/

CORONAVIRUS FREE ZONE PLEASE (unless it relates to good news about the environment)

Good one Celia, imagine having to do that, keep you fit though LOL.

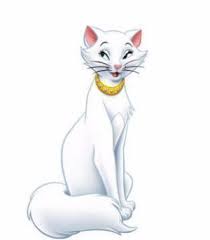

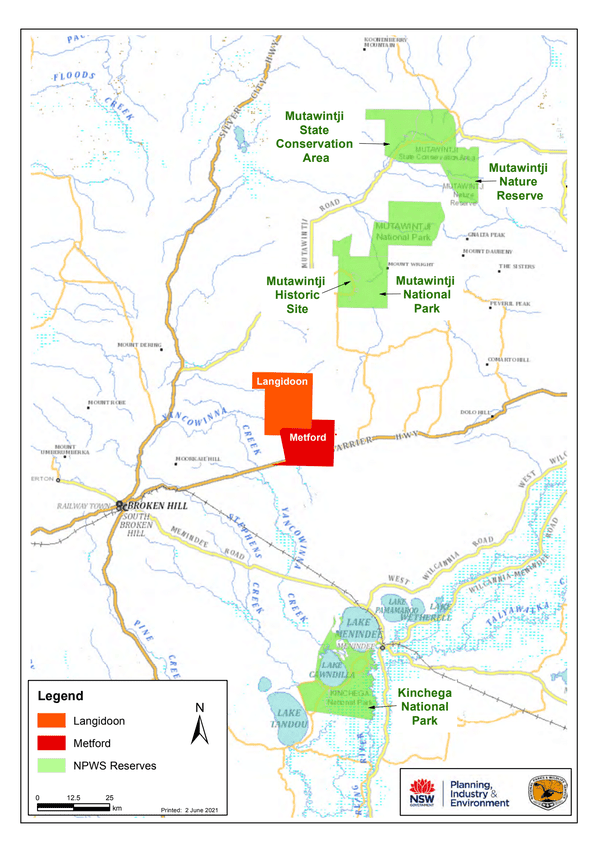

NSW buys 60,000 hectares of farmland near Broken Hill for outback nature reserve

Purchase of Langidoon and Metford sheep stations is the second-biggest national parks land procurement in NSW in the last decade The Langidoon and Metford sheep stations in western NSW – newly procured by the state government for use as a nature reserve – are home to at least 14 threatened species.

The Langidoon and Metford sheep stations in western NSW – newly procured by the state government for use as a nature reserve – are home to at least 14 threatened species.

The New South Wales government has purchased more than 60,000 hectares of farmland near Broken Hill for an outback nature reserve, home to at least 14 threatened species.

In an effort to expand conservation efforts in the traditionally underrepresented far west of the state, on Monday NSW environment minister Matt Kean announced the government had finalised the purchase of the neighbouring Langidoon and Metford sheep stations.

The amount paid for the 60,468 hectares of land – located 65km east of Broken Hill – has not been made public, but it’s understood it was funded by NSW environmental trust.

This purchase represents the second-biggest national parks land procurement in NSW in the last decade, preceded only by the acquisition of the 153,415 hectare Narriearra station in the state’s far north-west in June last year.

A map showing the purchased land. Photograph: NSW government

A map showing the purchased land. Photograph: NSW government

The stations stretch across sandplains, stony desert and shrubland, and are located in a bioregion that has one of Australia’s lowest levels of reservations – only 3.4% of the land is currently protected. The Treloar and Metford creeks also run through the properties.

“Land to the west of the Great Dividing Range supports a great diversity of wildlife, unique natural heritage and culturally important places, worthy of protection,” Kean said in a statement.

The government said the properties contain important Aboriginal heritage sites and artefacts, such as grinding plates and stones.

The area is also home to a number of threatened animal species.

“This new park will be an important refuge for wildlife including at least 14 threatened animal species including habitat for the Australian bustard, white-fronted chat and the pink cockatoo,” Kean said.

The threatened blue-billed duck and freckled duck are also found in the region, and 30% of this new reserve will be made up of endangered Acacia loderi shrublands.

The government will now begin the process of legally converting the stations into national parkland, which is expected to take several months.

“In time, it is expected visitors will be able to explore sandplains and stony desert, gibber chenopod shrublands, floodplain woodland along watercourses and a lake system that provides habitat for a range of migratory bird species,” a spokesman for the minister said in a statement.

It is hoped the former sheep stations will become an important refuge for wildlife. Photograph: NSW government

It is hoped the former sheep stations will become an important refuge for wildlife. Photograph: NSW government

In 2019 the NSW environment minister committed to increasing the national park system by 200,000 hectares. When this goal was reached nearly a year early it was doubled to a target of 400,000 by the end 2022.

Once this addition is formally reserved, the national parks system will have increased by more 350,000 hectares since August 2019, well on the way to meet the target of an additional 400,000 hectares by the end of 2022.

The land encompasses two ecologically important subregions: the Barrier Ranges which is currently unrepresented in the state’s national parks, and the Barrier Range Outwash subregion.

Good news indeed

A Tasmanian social enterprise has sold more electric vehicles in the state than Tesla through its bulk buy model and is now helping motorists in other jurisdictions access affordable second hand EVs

The Good Car Company introduced its used EV bulk buying model two and a half years ago to help make electric vehicles more affordable. Even with recent state-based incentives, such as the ACT’s stamp duty exemption, high upfront costs leave EVs out-of-reach for many.

Anthony Broese van Groenou, one of the organisation’s three founders, told The Fifth Estate the company is able to reduce costs by buying used cars from overseas in bulk on behalf of interested parties.

“We act as the aggregator to get the savings and pass them on.”

The first step is teaming up with a local council or community organisation to attract prospective EV owners though a series of local events. Broese van Groenou says this is where common EV myths are busted.

“We want to normalise the vehicles.”

While the cost of EVs remains the top barrier to EV adoption, Broese van Groenou says anxiety about shifting to new technology also holds people back. People feel much more comfortable once they’ve gone for a quick test run and spoken to an existing EV owner in their area.

He says range anxiety is still a common concern.

“Most people have this idea that Australians need to drive thousands of kilometres a day on the wide open plains but the reality is people only drive an average of 50 kms a day.”

Even the cheapest models can easily cover this distance, he says, and need only a couple of hours of charging between trips.

“It’s really about behaviour change – that’s why it’s so important for people get to experience driving an electric car and talking to owners.”

Broese van Groenou says many people are also pleasantly surprised to discover how cheap the vehicles are to maintain and run, saving the average Australian driver $1500 a year in fuel costs.

More info here:

NOT EXACTLY GREAT NEWS BUT COULD BE IF PEOPLE MADE BETTER CHOICES.

When thinking about the wealth gap and air travel, we tend to think of jet-setting millionaires in private planes or, more recently, Branson and Bezos popping zero-gravity champagne in the billionaire space race.

However, flight inequality is a growing problem for the planet on a much more common ground: frequent fliers.

A study from Global Environmental Change estimates that one per cent of the global population accounted for nearly half of all commercial flight emissions in 2018.

One popular proposal is a frequent flyer tax, intended to curb demand for flights rather than directly limit capacity.

British thinktank the New Economics Foundation estimates that in the UK alone, 15 per cent of the population is responsible for 70 per cent of commercial air travel while half the population does not fly at all.

This is not an outlier. In most high income countries, more than half the population does not fly in a given year, with that disparity growing higher as income decreases.

Oftentimes these trips aren’t even strictly necessary. A survey of students, a common frequent flier, found that one in five flights were redundant and had little to no importance to those flying.

So where are all of these people flying? A large chunk of the time, the flights are domestic or short haul.

Approximately 40 per cent of all passenger aviation emissions in 2018 were generated by domestic flights. One third of emissions came solely from flights under 1500 kilometres.

Domestic and short haul flights have a larger carbon footprint than long haul flights due to emissions heavy takeoff and landing cycles.

While the aviation industry plots its post-COVID return, it might be time to rethink how and where we fly.

One popular proposal is a frequent flyer tax, intended to curb demand for flights rather than directly limit capacity.

The first flight would see little to no tax, increasing incrementally with each additional flight. This would take some of the burden off those looking for a once-a-year family holiday while discouraging excessive flights.

The UK’s Climate Change Committee even recommended implementing the frequent flyer levy in a letter to the government as a way to limit aviation emissions, which threaten to become the country’s biggest emissions source by 2050.

There is of course the most direct method to creating a flight cap: cutting excessive flights.

In April, French lawmakers approved a measure banning domestic flights on routes that can be traveled within two and a half hours by train. The move is expected to slash 12 per cent of the nation’s domestic flights.

The legislation was watered down from the proposed four hour travel time after French airlines protested, many of them still hurting from pandemic flight restrictions. The bill also excludes connecting flights.

There are objections from both sides of the political spectrum with some claiming the bill would hurt French airlines and environmental advocates arguing it is a purely symbolic gesture.

Many consumers are actively choosing alternatives to flight, such as rail, out of both “flight shame” and sometimes convenience.

Rail tickets can often be cheaper and even comparable on overall travel time without the struggle of getting to and from isolated airports, standing in tedious security lines, waiting the recommended hour in the terminal and groaning when the flight gets delayed.

So the next time you’re sitting in an airport cursing that your hour-long flight has now exceeded the cost and time of an eight hour bus, consider ditching those frequent flyer miles for a train ticket. The planet — and your wallet — will thank you.

Series 3 Yarragon, Victoria : ABC iview

Hi Incognito.

I was watching over the weekend I think, on the ABC some great programmes, I was going to write them down but got side tract, not a good situation in my health at the moment. But this may be one of them, I really enjoyed them too. You probably already know about them, but there were a few of them.

Sorry to hear about your health not being good. I have watched a few of those episodes, but ended up feeling green with envy LOL, they spend a lot of money on those gardens, but good they use a lot of natives to attract local bee's and birds.

Are you ready for the new Hyundai Ioniq 5?Hyundai’s new electric midsize SUV ushers in a new era of clean mobility with an integrated rooftop solar panel to generate extra power on the road.Share on facebook Share on linkedin Share on email Hyundai’s Ioniq 5 electric vehicle explores new design freedoms made possible by its innovative electric battery platform.

Hyundai’s Ioniq 5 electric vehicle explores new design freedoms made possible by its innovative electric battery platform.

South Korean carmaker Hyundai is disrupting the electric vehicle market with its brilliant Ioniq 5.

Hyundai’s Ioniq 5 delivers on styling, quality and driver appeal. Hyundai has already proven to be a technology leader in the electric vehicle space and the Ioniq 5 takes it even step further with impressive specs.

The Ioniq 5 is Hyundai’s first vehicle to be built on a dedicated electric drivetrain – the e-GMP, short for electric Global Modular Platform. This means the vehicle is designed from the ground up with an electric drivetrain in mind, positioning the battery pack under the floor.

It’s the first Hyundai to offer an integrated rooftop solar panel that can directly power the car as well as cameras instead of exterior mirrors.

Hyundai’s Ioniq 5 is designed from the ground up to maximise electric vehicle technology.Innovative technology

Hyundai’s Ioniq 5 is designed from the ground up to maximise electric vehicle technology.Innovative technologyTech is at the forefront of the new Ioniq 5.

A large panoramic glass roof can be optioned with a solar panel that can feed 210Wh of electricity into the battery each hour, enough for around 1300km of driving over a year – provided the car gets plenty of sunlight.

The windscreen can be turned into an augmented reality display that transposes images and warnings across the outside view the driver is looking at.

Bluelink smartphone connectivity allows the car’s status and charging to be monitored remotely as well as cloud management of driver preferences such as seat position and radio settings.

Shake up marketThe Ioniq 5 is incredibly popular in its South Korean home market.

The Ioniq 5 will shake up Australia’s emerging EV market. It’s set to land in Australia later this year priced around the $70,000 mark, more affordable than the Tesla 3.

Its new e-GMP all-electric underpinnings allow for versatile cabin arrangements. A small front trunk adds between 24 and 57 litres to the 531-litres of boot space.

Batteries line the flat floor while compact electric motors – one at the rear for two-wheel-drive versions and another up front for all-wheel-drive models – take up minimal space.

With the ability to travel up to 480km between charges, the new mid-sized SUV can use its concealed lithium-ion battery pack to power a campsite, worksite or recharge an e-bike.

The Ioniq 5 will accept up to 350kW of electricity when charging, which is enough to add 100km of range in five minutes. A charge from 10 per cent battery capacity to 80 per cent is claimed to take 18 minutes when connected to those ultra-rapid chargers.

Key to its fast charging is an 800V electrical architecture – double that of most EVs – and the ability to transform a 400V connection into 800V.

Hyundai’s spacious interior features environmentally-friendly materials like eco-processed leather and bio-paint.Sprawling interior space

Hyundai’s spacious interior features environmentally-friendly materials like eco-processed leather and bio-paint.Sprawling interior spaceThe Ioniq 5 has abundant interior space due to its class-leading 3000mm wheelbase. It’s exceptionally roomy with more passenger space than larger SUVs.

The cabin has been thoroughly revised, with an emphasis on environmentally-friendly materials including eco-processed leather and bio-paint.

A universal island can slide back and forward 140mm, allowing those in the rear access to the wireless charging pad and creating a walk-through between the two front seats.

The driver-focused cabin includes a digital instrument cluster that can be tailored with images and notes virtually pinned to a customisable section alongside information such as the vehicle speed.

Modern styling and pixelated features extend to the grill and lights.Environmental shift

Modern styling and pixelated features extend to the grill and lights.Environmental shiftThe Ioniq 5 marks an environmental shift for the Korean automotive giant.

Previously an individual model, Ioniq is now Hyundai’s EV sub-brand that will spawn a family of vehicles built on their new electric architecture. Sister brands Genesis and Kia will use the same platform.

Hyundai plans to sell at least 12 different EV models by 2025 to help drive a more sustainable society.

Toyota hybrids had the solar roof panels on the roof for a number of years now.

I remember getting into my bro's car after it was sitting in the sun and it was quite cool.

Very nice I wouldn't mind one of those!

Australian company world first to use wasted wool from the underbelly of sheep to replace billions of tonnes of Polystyrene and compete against the US$28 billion world polystyrene market giving Australian and New Zealand sheep farmers increased revenueEco Voice | July 20, 2021

Since its launch in 2016 Planet Protector Packaging has been on a mission to save the environment from polystyrene by replacing it with Woolpack. Woolpack is created from the underbelly wool of sheep and has previously been sent to landfill as there has not been a commercial application for it.

Since its launch in 2016 Planet Protector Packaging has been on a mission to save the environment from polystyrene by replacing it with Woolpack. Woolpack is created from the underbelly wool of sheep and has previously been sent to landfill as there has not been a commercial application for it.

Polystyrene products fill up 30 per cent of landfills around the world.

Australians import 52,000 tonnes of polystyrene every year, only one quarter of which is recycled the remainder is sent to landfill.

Founder Joanne Howarth used to work for a company selling meal kits that used 35,000 polystyrene boxes every week. Ingredients would arrive in polystyrene boxes and then get distributed to the public in more polystyrene boxes.

“I used to have a forklift roster just to move the polystyrene boxes,” she says.

“I can’t tell you how much pushback we got from customers. They had no way to dispose of those boxes. There was a desperate need to get an alternative because polystyrene has dominated this space for 60 years.”

Planet Protector Packaging has 35 staff and is processing 20 tonnes of waste wool a week from Australian and New Zealand sheep.

“When sheep are sheared there are offcuts, like from the underbelly, that’s no good for the textile industry, so it was going to landfill. Farmers weren’t getting paid for the waste so they were losing revenue.”

The waste wool is encased in a recyclable plastic or compostable sleeve to line boxes and is used to cushion and insulate food and medical supplies.

“Wool is a remarkable fibre and the best insulator on the planet.” States Howarth.

Instead of being saddled with polystyrene that they don’t know what to do with, she says, her customers reuse the wool insulation to put in their shopping bags, hanging baskets, pet bedding and home compost.

On a mission to eliminate polystyrene from the world, Joanne’s efforts create a notable impact.

“We have diverted 2,600 tonnes of compressed polystyrene from the waste stream. This equates to 44 Olympic-sized swimming pools,” the entrepreneur says.

With annual revenues over AUD$5 million the company is poised to scale and will invest funds from a current capital raising on Birchal into expanding its operationswww.birchal.com/company/planetprotector.

It will build a wool manufacturing facility in Geelong, VIC, Australia’s wool capital, bringing this step of the processing back onshore. This will create jobs, support regional communities and farmers, and create a 100% sustainable alternative to EPS.

The company currently sends its wool to China for processing because there are no capabilities in Australia. By bringing wool processing back home to Australia, it will drive wool manufacturing into the future. The facility will not only create jobs but also reduce our reliance upon China.

Howarth said, “We use waste wool that is destined for landfills and we create environmentally responsible packaging that replaces expanded polystyrene in the packaging supply chains. It gives sheep farmers another income stream, stops filling our landfills, and saves our oceans. For our clients, it’s another way they can tick the environmentally responsible box” and this is what all businesses are looking to achieve as the world transitions to a circular economy”.

Planet Protector Packaging has replaced over 7.5 million polystyrene boxes and its clients include many iconic brands the likes of Blackmores, Baxters, The Dinner Ladies, and more.

Interesting story thanks Incognito. Great project.

Nickel-rich sap coming from Phyllanthus rufuschaneyi/Anthony van der Ent, UQ

Nickel-rich sap coming from Phyllanthus rufuschaneyi/Anthony van der Ent, UQ

Big tropical mining companies could soon be presented with a green alternative to traditional strip mining by letting plants hoover up the trace minerals instead of mining equipment.

Phytomining, as it’s called, relies on a select few species of plants that can literally suck the soil dry of minerals like zinc, selenium, nickel, and cobalt.

Rather than polluted rivers, plumes of sulfur dioxide, and the throng of heavy machinery, phytominin—as one demo site which started in 2015 bears witness—relies on locals to trim a few feet of a 20-feet tall green shrub. These leavings are collected and burned to create “bio-ore” filled with 20 to 25% nickel by weight.

The mining industry is keen to see how this green alternative to one of the most carbon-heavy industries can actually perform. Allowing plants to gather materials for you beats rooting around for it in the ground on a remote island like Borneo.

“We can now demonstrate that metal farms can produce between 150 to 250 kilograms of nickel per hectare (170 to 280 pounds per acre), annually,” Antony van der Ent, a senior research fellow at Australia’s University of Queensland, told Grist, in a special report on phytomining in Indonesia.

MORE: Professor Develops Technology That Cools People Down – Without Electricity or AC

“At this stage, phytomining can go full-scale for nickel immediately, while phytomining for cobalt, thallium, and selenium is within reach,” van der Ent said.

Farming metalNickel mining companies might be drooling over the scientific modeling van der Ent and other “metal farmer” experts have done that found nickel phytomining to be on a similar cost basis to corn farming, but with an after-production gross of around $1,800 per hectare—making it a very profitable activity.

While the Grist report details phytomining in Borneo, trials have been done in the U.S.A, Italy, Albania, Canada, France, Spain, and New Zealand. There are around 700 recognized “hyperaccumulators,” which is the term for plant species that can absorb large quantities of these minerals before depositing them in their shoots, branches, and leaves.

There are some parallels to food agriculture, for example the amendment of calcium is vital, while nitrogen and organic material supplementation seem to increase the available nickel in plant shoots.

CHECK OUT: Solar-Powered Refrigeration Trucks Will Cut Pollution From Idling Diesel Engines

By far the most advantageous aspect of phytomining if you run a major mining corporation is actually not where the soil is rich, but where the soil is poor, in nickel. At concentrations of 1% or less, the only option is to strip mine, for example in locations like Brazil, Cuba, Indonesia, the Philippines, and New Caledonia.

It involves taking a surface layer of rock and soil off a stretch of ground, and using acid-leaching heavy machinery to extract the scarce nickel particles. All this unhappy work for very little metal results in a layer of toxic topsoil filled with trailing metal particles that has to be collected and sold to landfills at great cost to the miners.

Very interesting

Agree Suze.

Today, the U.S. Food and Drug Administration approved the first COVID-19 vaccine. The vaccine has been known as the Pfizer-BioNTech COVID-19 Vaccine, and will now be marketed as Comirnaty (koe-mir’-na-tee), for the prevention of COVID-19 disease in individuals 16 years of age and older.

The vaccine also continues to be available under emergency use authorization (EUA), including for individuals 12 through 15 years of age and for the administration of a third dose in certain immunocompromised individuals.

Great news for the environment, healthier countries, less lockdowns. More businesses insisting staff have the vaccine. Now many will follow SPC and Qantas. Get vaccinated and contribute to a safe environment!!! Do your bit for the country and the world!!!

I will refrain from calling you want I think you are, but here you are again playing your silly games, this is a covid free topic, there are heaps of covid threads you can post on.

Not good for the environment unless they recycle all those little vials, masks, needles, swabs etc. Any suggestions? What a mountain of landfill!!

ADVANCED RECYCLING TURNING PLASTIC WASTE INTO RESOURCES

The report, Advanced recycling technologies to address Australia’s plastic waste, which was released today, evaluates the ways to convert plastic waste that can’t be recycled with existing methods, into new resources to build Australia’s circular economy.

It is estimated that 130,000 tonnes of plastic leaks into the Australian marine environment each year. Less than 12 per cent of plastic waste is recycled and about 85 per cent ends up in landfill.

Advanced recycling of plastic waste, also referred to as feedstock, molecular, or chemical recycling, converts plastic waste into its chemical building blocks and back into plastic, or other useful resources such as fuel.

CSIRO researcher Ms Sarah King said with new waste plastic export rules in place, new technologies were critical to support the increased recovery and recycling of plastics.

"Advanced recycling technologies could turn hard-to-recycle plastics, such as mixed, multi-layer, flexible or contaminated plastics back into food grade recycled plastics or other products through chemical, thermal or biological processes," Ms King said.

"It is suitable for flexible or soft 'scrunchable' plastics used for food packaging, such as food pouches and chocolate wrappers. When collected, these types of plastics may be contaminated with food, or mixed with other materials so currently can't be recycled.

"Advanced recycling could process this plastic waste to increase opportunities for the polymer manufacturing and waste sectors by supporting new industries. The North American market is estimated at $120 billion, demonstrating there is economic potential for adopting advanced recycling in Australia."

Australia has set a national target of 70 per cent of plastic packaging recycled or composted by 2025, and 80 per cent average recovery rate from all waste streams by 2030.

Chemistry Australia's Director for Strategy, Energy and Research Peter Bury, who collaborated with CSIRO on the report, said advanced recycling is an important and complementary technology able to progress an Australian plastics circular economy.

"Mechanical recycling methods are our foundation technologies and very effective for a range of well-sorted plastics used for food and other packaging. Advanced recycling can sit alongside these to further strengthen Australia's recycling capabilities for plastics that can't be processed through existing channels," Mr Bury said.

"Australia already has the critical industrial capability in polymer manufacturing, steam crackers, and refineries, to integrate advanced recycling outputs to produce new polymers. Importantly, we have the talented and skilled people in place to introduce and develop this additional technology."

The report and opportunities to adopt advanced recycling technologies are key parts of CSIRO's developing Ending Plastic Waste Mission to achieve an 80 per cent reduction of plastic pollution entering the Australian environment by 2030.

"Our report aims to build awareness of advanced recycling technologies, how they apply to different plastic types, and the key factors to enable adoption and scale up of these technologies in Australia," CSIRO's Ms King said.

"Plastic pollution and waste are challenges we need to solve. Advanced recycling will improve the recovery, recycling and reuse of materials, consistent with a circular economy."

Great news after so many of our waste products being exported.

Excellent news, thanks Incognito.

Floating wind catcher by Norwegian company Wind Catching Systems produces renewable energy for 80,000 homes at prices comparable to traditional fossil fuels.

The windcatchers are designed for a lifespan of 50 years compared to the 20 years of a traditional turbine

Thanks for that added info Suze, it is so interesting that new technologies are appearing more and more, like the waste issue above, we live in hope that things can and hopefully will improve.

I am not as hopeful as you Incognito ... not as long as the human vermin continues to breed and overpopulates the earh.

Organic food has been a hot topic for some now, but what really is the difference? And, why should you care? Read on to learn the basics on organic food and farming and its benefits for both you and the earth!

Food and ingredients produced via organic farming is food that is as natural as can be. Organic always means:

No synthetic chemicals, pesticides or herbicides

Made without artificial colours or preservatives

Livestock are free to roam

No routine use of antibiotics

No genetically modified ingredients (GMOs)

HOW IS ORGANIC FOOD BETTER?

Tossing up between organic and non-organic products? Not sure why organic products are more expensive? Here are just a few reasons why you should shop organic!

It’s more nutritious. Studies have shown that organic food contains more vitamins, minerals and micronutrients than conventionally grown food.

There are no harmful pesticides used. This means no residue on the food you are eating and the farmers are not exposed to constant chemicals - and neither is the earth!

There are no artificial additives. Organic produce has no artificial ingredients, chemical flavourings, MSG or preservatives (including sulphur dioxide).

It tastes better! The careful organic farming practices that emphasise quality over quantity, the better welfare of animals and the lack of any filler ingredients allow the natural flavours of the food to shine through.

HOW DOES ORGANIC FARMING BENEFIT THE ENVIRONMENT?

Organic food isn’t just better for your health, it is also better for the environment! Organic farming practices:

Prevents the use of toxic chemicals. These chemicals can be damaging to our environment, wildlife and health.

Build healthy soil. Healthy soil is the basis for organic agriculture. Organic farmers use natural resources to maintain healthy soil that can sustain generations.

Encourage biodiversity. Organic farms respect the natural biodiversity of their environment, creating stable habitats for local wildlife and increasing how resilient a farm is to issues like bad weather, disease and pests.

Reduces pollutants in water health. When pesticides and fertilisers are used, damaging runoff can end up in our waterways.

THE CERTIFICATION PROCESS

While anyone can claim their product is organic, a certifying logo is your proof that the product you are buying not only talks the talk but walks the walk.

To be certified organic, farmers must undergo audits over a 3-year period and continue to be audited to hold onto the organic certification. The audits are to ensure the growing and manufacturing process is up to Australia’s organic standards and the 3-year period is to ensure full organic compliance.

AUSTRALIAN CERTIFICATION BODIES

In Australia, there are various organic certification bodies that have been approved by the Australian Quarantine and Inspection Service (AQIS), such as:

Australian Certified Organic (ACO)NASAA Certified OrganicThe Organic Food ChainAUS-QUALThe Bio-Dynamic Research InstituteSafe Food Production QueenslandThe Tasmanian Organic ProducersIFOAM

DID YOU KNOW?

Australia has the largest agriculture land under certified organic. 23 million hectares and growing!

No I did not know that Australia had 23 million hectares certified organic .. it is a surprise to me

Me too, but it is great news, because the demand for chemical free food is growing world wide. The more people buy it the cheaper it will get in the long run.

Tens of Millions Now Have Power Thanks to Off-Grid Solar Systems –Many of Them Recycled  Jon Strand, CC license

Jon Strand, CC license

While in America off-grid solar electricity is still fairly uncommon, around the world it gives power to 420 million people.

Furthermore, it’s created an entirely unlooked-for market worth more than $1 billion annually. It’s unlooked-for because—as the first and even second generations of solar panels are nearing the end of their lifecycle—renewable energy pioneers and advocates are hurrying to try and come up with ways to prevent them from inundating landfills with millions of tons of electronic waste.

The International Renewable Energy Agency reports that, by 2050, there will be only slightly more new panels installed per year than there will be panels being decommissioned—and they are predicted to grow to 6% of global electronic waste streams.

MORE: Solar-Powered Refrigeration Trucks Will Cut Pollution From Idling Diesel Engines

The solution to the problem of growing solar waste, is perhaps seeing that a degraded solar panel just needs a slight fix to make it nearly as good as new.

Since 2017, revenues from the off-grid solar industry continue to rapidly grow, increasing by 30% annually, report the World Bank, who add that 180 million off-grid solar panels were sold to people in countries including Nigeria, Pakistan, and Lebanon.

In nations such as these, reliable power for those outside the major cities is hardly the norm. Poor infrastructure and limited investment currently restricts electricity access to about one-ninth of the world’s population.

While perhaps not good enough to maintain government or industry-imposed standards for power generation at a Google campus, decommissioned solar panels are often just fine for meeting the needs of powering a house, or a water pump, or something equally small.

A little opinion piece in Bloomberg remarking on these recent reports noted that second-hand market shipments of retired solar panels in the several thousands are quite the normal.

RELATED: Shade From Solar Panels Increases Abundance of Flowers, Benefiting Pollinators

In the Southern Hemisphere, merely an $11 billion investment at current market conditions would be needed to expand the second-hand solar trade to every unpowered inhabitant.

“The off-grid solar industry is instrumental for achieving universal electricity access,” said Riccardo Puliti of the report, the Regional Director of Infrastructure, Africa, at the World Bank. “We are scaling up our support to client countries by helping them leverage this potential through innovative and financially sustainable solutions.”

I hope this is on the correct topic, my site is not that brilliant this morning!

But it looked fun.

Pedal-Powered Generators Save You Money | MOTHER EARTH NEWS

Bushfires 1: Understanding bushfires - Curious (science.org.au)